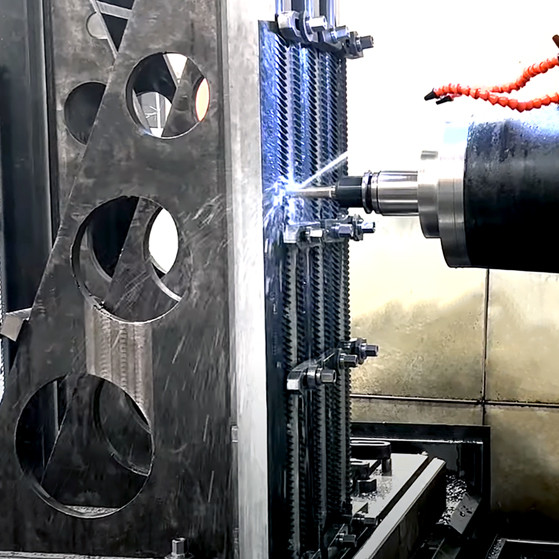

Welded Manufacturing

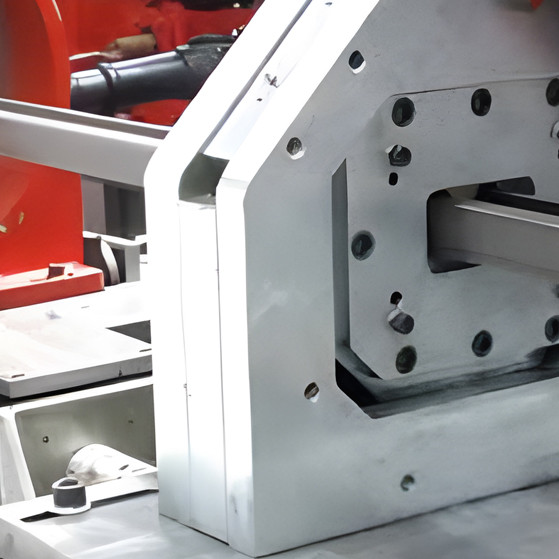

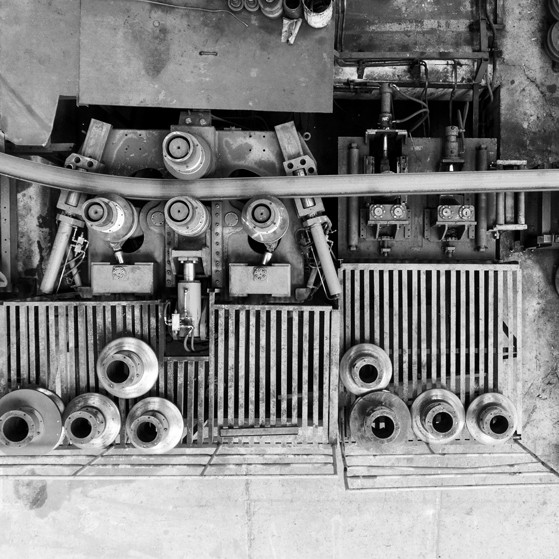

In the Welded Manufacturing unit within the scope of Kocaer Service Center, productions are carried out in accordance with electric Arc, Mig-Mag and Submerged Submerged arc welding methods. Welded production of our hot rolled products and other iron-steel products is carried out in accordance with the standards and delivered as the final product, in line with the project-specific and customer demands. In particular, welded manufacturing of steel structures, special facility construction, solar energy construction systems, mine and tunnel support systems is carried out with fixtures and certified personnel suitable for the project.